Tel.: 8615989623158

E-mail: sales@grandetop.com

Tel.: 8615989623158

E-mail: sales@grandetop.com

ES series electromagnetic vibration testing system simulates the vibration environment under the laboratory condition,and test the impact strength as well as reliability of various vibration test applications.In the laboratory ,with the aid of vibration testing system,model simulation of reproduction of sinusoidal.random,resonant search and dwell, classical shock and simulation,etc.can be achieved.It is essential for product quality assurance,new product research and development.

ES series electromagnetic vibration testing system is specially designed to meet the need for long time operation. installation of vibration resistant base can achieve vertical and horizontal vibration. The standard platform is installed with high efficiency airbag shock isolation device so that the vibration transmitted to the building can be minimized, at the same time avoid the need of additional foundation in most of the cases.

A complete set of vibration testing system is composed of shaker. power amplifier and vibration measuring control system.in

accordance with the relevant national and international standards(such as:. MIL-STD. DIN.ISO.ASTM,IEC.ISTA,GB.GJB,JIS.BS.etc.) to provide technical support for establishing product quality inspection.

Features

1,Rugged suspension system and linear motion guiding.strong carrying capacity.good guiding functions, high stability

2,Load center airbag has high static stiffness and low dynamic stiffness.strong carrying capacity, perfect performance on amplitude variation

3,High efficiency D class power switching, 3-sigma peak current provide finest power consumption and minimize harmonic distortion

4,Quick self-diagnosis with safety interlock, high safety reliability Airbag shock isolation device for vibration platform without the need of additional foundation, perfect reproduction of vibrational wave and reduce vibration transmittance

5,Provide horizontal and vertical expansion platform for different application.

Simple controller operation

Vibration test machine is used to test the objects/products property in a vibration Transportation environment,such as boat, car, truck and train. It is widely applied

to electronic, electrical and mechanical, photoelectric, auto-mobile, toys, packaging, etc.

Main features:

1. LCD computer control, easy operation.

2. Even vibration, easy to adjust amplitude, predicate amplitude.

3. Large amplitude adjustment range, low noise.

4. Human engineering design.

5. Fixed frequency, sweep frequency and multistage random test function.

Testing methods:

Random Vibration Testing replicates complex frequencies in a chosen bandwidth. Vibration environments may have input from multiple sources, such as wheels over a road. In these vibration exposures, it may be more accurate to analyze and test using random vibration.In random vibration the primary concern is the spectral content of the vibration being generated.

Most random vibration tests are conducted using Gaussian random suppositions where maximum amplitude is not definable,and levels are measured in RMS values. Sinusoidal Vibration Testing with sinusoidal vibration,the relationship betweenacceleration,

velocity and displacement is fixed and frequency dependent. Variation in any one of

these three parameters affects another, and for this reason, all of them should be

considered simultaneously when specifying or observing sine vibration.Sine Sweep Vibration Testing: are sweeps across a frequency spectrum at a specific rate to

identify resonant frequencies of a Unit Under Test (UUT).Sine Dwell Vibration Testing

are dwells at a specific frequency, often at a resonant frequency, to duplicate a worst case condition for the UUT. Sine-on-Random Vibration Testing is performed by overlaying a sine dwell on a random vibration profile.

Vibration Test Systems Selection Guide

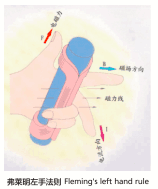

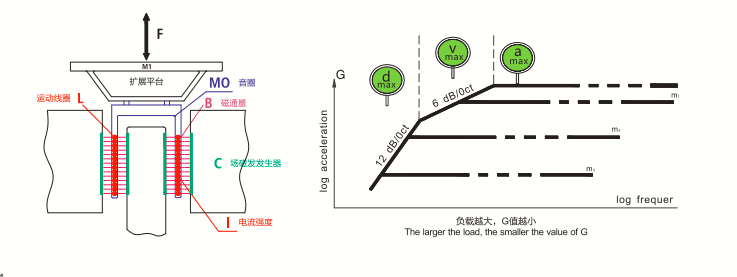

The Working Principle of Vibration Exciter

The Working Principle of the electromagnetic vibration exciter is similar to a loudspeaker whereby electrical conductor is moved by

the action of electromagnetic force in the magnetic field.The force to accelerate the moving part is generated by the balance between driving current and magnetic flux. Therefore,by controlling the driving current,one can control of the vibration generator.

The maximum acceleration level of the electromagnetic vibration exciter is determined by the maximum current and the load,At low frequency,displacement of moving part will limitation and the acceleration will not reach high level,The resonance frequency of the moving element is set higher than the upper limit of the frequency range.

The performance of vibration generator can be reflected by the chart that display the maximum acceleration under different frequency.By using a log-log plot,the displacement can be restricted to a linear representation with slope of 6 dB/octave.

Exciting force(N)

F=B*1*L Magnetic field intensity(T)

Current(A)

Length(m)

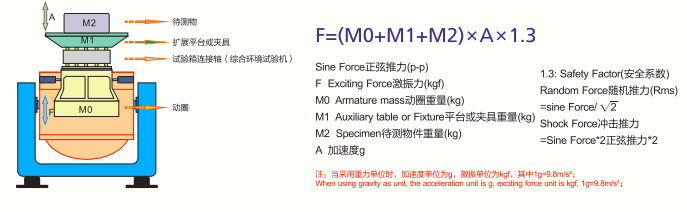

Test requirements and model selection guide

To choose a suitable vibration test system,the most important thing is to know the exciting force required to perform the vibration test.To evaluate and calculate the exciting force,the following test specifications should be known:

l Clear Testing Requirements

l Maximum Displacement

l Frequency(Frequency Range)

l Maximum Velocity

l Maximum Acceleration

l Specimen Mass and Fixation

The specimen fixation is selected based on the upper limit of test frequency and specimen size,either vertical expansion platform or horizontal slip table,Specimen mass is needed to evaluate the required exciting force for vibration test

Evaluation of Armature Mass

When evaluating the exciting force needed for vibrating test,you can choose a temporary armature mass(according to the model of EV series).

Calculate the required excitation force

Vibration test machine selection guide

Air cooling Vibration Test Systems

Air Cooling Electromagnetic Test System takes the advantages of wide frequency range,reliability,small in size,easy to move,easy operation.,etc.We are providing a lots of models for your options.Sine force range is from 1KN to 70KN,the loading capacity is from 70KGs to 1000KGs.We are also providing the integrated climatic simulations and mechanical test equipment.

Features

1,Sine force range:1kN~70kN

2,High quality Spring,Excellent performance for Low Frequency.

3,Ratio of Random and Since force:1:1

4,Excellent Magnetic Uniformity.

5,Expand 2 times Sinusoidal Excitation Force.(Option 3 Times)

6,Sine,Random,Shock.,etc test.

7,Max Displacement(P~P(mm)):25mm,40mm,51mm,76mm or 100mm

8,Excellent performance of Blower,low noise and long life.

9,Optimization design of Armature:Light,Excellent Resistance Vibration

Technical parameters:

| Model | ES-1-150 | ES-1S-150 | ES-2-150 | ES-2-230 | ES-3-150 | ES-3-230 | ES-6-230 | ES-10-240 | ES-10d-240 | |||

| Φ60Φ120Φ15013×MB | Φ100Φ200Φ23017×MB | Φ60Φ120Φ15013×MB | Φ100Φ200Φ23017×MB | Φ100Φ200Φ23017×MB | Φ100Φ200Φ24017×MB10 | |||||||

| Rated random excitation force/Sinusoidal excitation force(KN) | 1 | 1.5 | 2 | 2 | 3 | 3 | 6 | 10 | 10 | |||

| Shock Force(KN) | 2 | 3 | 4 | 4 | 6 | 6 | 12 | 20 | 20 | |||

| Frequency Range(Nz) | 5-4500 | 5-4500 | 5-4500 | 5-2500 | 5-4000 | 5-2500 | 5-3500 | 5-3000 | 5-5000 | |||

| Max Acceleration(m/s²) | 500 | 750 | 1000 | 250 | 1000 | 350 | 1000 | 1000 | 1000 | |||

| Max Speed(m/s) | 2 | 2 | 2 | 1.5 | 2 | 1.5 | 1.8 | 1.8 | 1.8 | |||

| Max Displacement P~P(mm) | 25 | 25 | 25 | 40 | 25 | 40 | 51 | 51 | 51 | |||

| Max Loading(kg) | 70 | 70 | 70 | 140 | 120 | 140 | 300 | 300 | 300 | |||

| Shaker Model | ET-1 | ET-1.5 | ET-2 | ET-2 | ET-3 | ET-3 | ET-6 | ET-10 | ET-10d | |||

| Equivalent Mass of Moving parts(kg) | 2 | 2 | 2 | 8 | 3 | 8.5 | 6 | 10 | 10 | |||

| Size of head expander(Working table)(mm) | 150 | 150 | 150 | 230 | 150 | 230 | 230 | 240 | 240 | |||

| Weight(kg) | 395 | 395 | 395 | 430 | 480 | 430 | 590 | 900 | 900 | |||

| Size L×W×H(mm) | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 2.5 | 2.5 | |||

| Power Amplifier Model | SDA-1 | SDA-1S | SDA-2 | SDA-2 | SDA-3 | SDA-3 | SDA-6 | SDA-10 | SDA-10 | |||

| Power Amplifier(KVA) | 1 | 1.5 | 2 | 2 | 3 | 3 | 6 | 10 | 10 | |||

| Power Supply(KVA) | 4 | 4.5 | 5.5 | 5.5 | 6.5 | 6.5 | 16 | 21 | 21 | |||

| Weight(kg) | 160 | 160 | 200 | 200 | 200 | 200 | 240 | 400 | 400 | |||

| Size L×W×H(mm) | 607×820×1593 | |||||||||||

| Cooling Method | Forced air cooling | |||||||||||

| Blower Model | B-200 | B-200 | B-200 | B-200 | B-200 | B-200 | B-1000 | B-1000 | B-1000 | |||

| Power(KW) | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 4 | 4 | 4 | |||

| Rate of flow(m³/s) | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.33 | 0.33 | 0.33 | |||

| Pressure(kpa) | 1 | 1 | 1 | 1 | 1 | 1 | 3.5 | 3.5 | 3.5 | |||

| Weight(kg) | 30 | 30 | 30 | 30 | 30 | 30 | 115 | 115 | 115 | |||

| Model | ES-20-320 | ES-20-445 | ES-30-370 | ES-30-550 | ES-40-370 | ES-40-445 | ES-50-445 | ES-60-445 | ES-20LS3-3 |

| Φ120Φ250Φ32017×M10 | Φ200Φ400Φ44517×M10 | Φ150Φ300Φ37017×M10 | Φ200Φ300Φ400Φ500Φ55033×M10 | Φ150Φ300Φ37017×M10 | Φ200Φ250Φ32017×M10 | Φ100Φ200Φ300Φ34021×M10 | |||

| Rated random excitation force/Sinusoidal excitation force(KN) | 20 | 20 | 30 | 30 | 40 | 40 | 50 | 60 | 60 |

| Shock Force(KN) | 40/60* | 40/60* | 60/90* | 60/90* | 80/120* | 80/120* | 100/150* | 120/180* | 40/60* |

| Frequency Range(Nz) | 5-3000 | 5-2800 | 5-2800 | 5-2000 | 5-2800 | 5-2700 | 5-2700 | 5-27700 | 5-3000 |

| Max Acceleration(m/s²) | 1000 | 700 | 1000 | 500 | 1300 | 800 | 1000 | 1000 | 800 |

| Max Speed(m/s) | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Max Displacement P~P(mm) | 51 | 51 | 51 | 51 | 51 | 51 | 51 | 51 | 76 |

| Max Loading(kg) | 300 | 300 | 500 | 500 | 500 | 800 | 800 | 800 | 800 |

| Shaker Model | ET-20 | ET-20 | ET-30 | ET-30 | ET-40 | ET-40 | ET-50 | ET-60 | ET-20LS3 |

| Equivalent Mass of Moving parts(kg) | 20 | 28 | 30 | 55 | 35 | 50 | 50 | 60 | 25 |

| Size of head expander(Working table)(mm) | 320 | 445 | 370 | 445 | 445 | 445 | 445 | 445 | 340 |

| Weight(kg) | 1695 | 1700 | 2490 | 2540 | 2490 | 4500 | 4500 | 4500 | 1695 |

| Size L×W×H(mm) | 1222×760×1052 | 1328×854×1140 | 1328×854×1158 | 1328×854×1140 | 1730×1139×1272 | 1222×760×1067 | |||

| Power Amplifier Model | SDA-20 | SDA-20 | SDA-30 | SDA-30 | SDA-40 | SDA-40 | SDA-50 | SDA-60 | SDA-20 |

| Power Amplifier(KVA) | 20 | 20 | 30 | 30 | 40 | 40 | 50 | 60 | 25 |

| Power Supply(KVA) | 44 | 44 | 54 | 54 | 73 | 73 | 82 | 95 | 44 |

| Weight(kg) | 450 | 450 | 500 | 500 | 500 | 550 | 550 | 700 | 450 |

| Size L×W×H(mm) | 620×1010×2106 | 607×820×1593 | |||||||

| Cooling Method | Forced air cooling | ||||||||

| Blower Model | B-2000LN | B-2000LN | B-3000 | B-3000 | B-5000 | B-5000 | B-5000 | B-7000 | B-2000LN |

| Power(KW) | 7.5 | 7.5 | 7.5 | 7.5 | 1.5 | 1.5 | 1.5 | 22 | 7.5 |

| Rate of flow(m³/s) | 0.46 | 0.46 | 0.46 | 0.46 | 11 | 11 | 11 | 1.6 | 0.46 |

| Pressure(kpa) | 3.5 | 3.5 | 8.8 | 8.8 | 7.7 | 7.7 | 7.7 | 8 | 3.5 |

| Weight(kg) | 140 | 140 | 180 | 180 | 255 | 255 | 255 | 340 | 140 |

| Model | ES-30LS4-445 | ES-40LS4-445 | ES-50LS3-445 | ES-60LS3-445 | ES-50LS4-445 | ES-60LS3-445 | ES-50LS4-445 | |

| Φ200Φ400Φ44517×M10 | Φ200Φ400Φ44517×M12 | Φ200Φ300Φ400Φ500Φ55033×M12 | ||||||

| Rated random excitation force/Sinusoidal excitation force(KN) | 30 | 40 | 50 | 60 | 50 | 60 | 70 | |

| Shock Force(KN) | 60/90* | 80/120* | 100/150* | 120/180* | 100/150* | 120/180* | 140/210* | |

| Frequency Range(Nz) | 5-2600 | 5-2600 | 5-2600 | 5-2600 | 5-2600 | 5-2500 | 5-2500 | |

| Max Acceleration(m/s²) | 750 | 900 | 900 | 1000 | 900 | 730 | 850 | |

| Max Speed(m/s) | 1.8 | 1.8 | 2 | 2 | 2 | 1.8 | 1.8 | |

| Max Displacement P~P(mm) | 100 | 100 | 76 | 76 | 100 | 76 | 76 | |

| Max Loading(kg) | 500 | 500 | 800 | 800 | 800 | 1000 | 1000 | |

| Shaker Model | ET-30LS4 | ET-40LS4 | ET-50LS3 | ET-60LS3 | ET-5OLS4 | ET-60LS3 | ET-70LS3 | |

| Equivalent Mass of Moving parts(kg) | 40 | 45 | 55 | 55 | 56 | 82 | 82 | |

| Size of head expander(Working table)(mm) | 445 | 445 | 445 | 445 | 445 | 550 | 550 | |

| Weight(kg) | 2540 | 2540 | 4500 | 4500 | 4500 | 7300 | 7300 | |

| Isolation Frequency(Hz) | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | |

| Size L×W×H(mm) | 1328×854×1213 | 1730×1139×1293 | 1730×1139×1348 | 1820×1297×1373 | ||||

| Power Amplifier Model | SDA-30 | SDA-40 | SDA-50 | SDA-60 | SDA-50 | SDA-60 | SDA-70 | |

| Power Amplifier(KVA) | 30 | 40 | 50 | 60 | 50 | 70 | 70 | |

| Power Supply(KVA) | 54 | 73 | 82 | 95 | 82 | 95 | 108 | |

| Weight(kg) | 500 | 550 | 550 | 700 | 550 | 550 | 700 | |

| Size L×W×H(mm) | 620×1010×2106 | |||||||

| Cooling Method | Forced air cooling | |||||||

| Blower Model | B-3000 | B-5000 | B-5000 | B-7000 | B-5000 | B-7000 | B-7000 | |

| Power(KW) | 7.5 | 15 | 15 | 22 | 15 | 22 | 22 | |

| Rate of flow(m³/s) | 0.46 | 11 | 11 | 1.6 | 11 | 1.6 | 1.6 | |

| Pressure(kpa) | 7.7 | 7.7 | 7.5 | 7.7 | 7.5 | 7.5 | ||

| Weight(kg) | 180 | 180 | 255 | 340 | 255 | 340 | 340 | |