Tel.: 8615989623158

E-mail: sales@grandetop.com

Tel.: 8615989623158

E-mail: sales@grandetop.com

UL1581 horizontal and vertical burning test equipment (also known as UL wire and cable combustion chamber,or UL-resistant wire and cable burning test device)

In accordance with UL1581/ UL2556, ASTM D 5025/ASTM D 5207 standard requirements for testing wire insulation or fire performance of coated body dedicated test machine.

Los equipos de combustión / La máquina/cámara de combustión

On summary:

UL1581 horizontal and vertical burning test equipment (also known as UL wire and cable combustion chamber,or UL-resistant wire and cable burning test device)

In accordance with UL1581/ UL2556, ASTM D 5025/ASTM D 5207 standard requirements for testing wire insulation or fire performance of coated body dedicated test machine.

By UL engineers guidance, self-designed automatic electrical and mechanical structure system user-friendly design, just press a start button, auto-completion test, the test results in the formation of the report format LCD displays, will minimize human errors truly ensure the accuracy and reliability of test results.

Automatic models compared to manual operation can greatly reduce labor intensity and improve the accuracy of the test,and the operator to completely avoid being poisoned by smoking, particularly suitable for detecting a large number of agencies and manufacturers to use, fully able to meet UL1581 section 1060 (and FT1 vertical flame test), Festival (VW-1 flame test)1080,section 1090(appliances with a line horizontal burning test),section 1100(horizontal specimen/FT2 burning test)the relevant standards.

The parameters and features:

1,chamber volume: 4.6m3

2,Carton Size: L2000*W1265*H2345mm

3,Spitfire: automatic electronic ignition

4,The test box: with aluminum frame and electrolytic plate electrostatic spraying, with the appearance of beautiful, rust and corrosion, etc.

5,At the top of the box has a power ventilation exhaust system .when the test is complete, open simultaneously with the air supply system, can exhaust emissions to the outdoors; testing process, this system is a closed state.

6,Withing a blast cabinet inside. When the test is complete, the ventilation system is turned on, the air inside. during the test, this should be closed off.

7,The front of the box isn’t in the process of testing, you can seal the glass viewing window to observe, easy to observe the test case.

8,There is a glass viewing window in the bottom,from the window the hand and arm can operated.The hole with sealing glove,the glove an operator to operate the sealing combustion torch. Operator using sealed glove combustion burner operation.

Technical parameters:

| Model No | GBNT | |

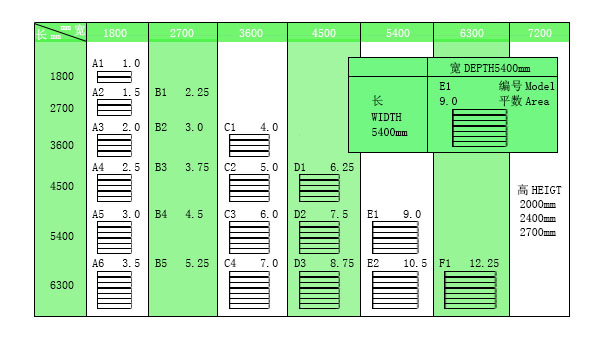

| Inner chamber size(mm)W*H*D | Please check the size chart | |

| Exterior chamber size(mm)W*H*D | ||

| Temperature range | R.T+10℃~+80℃ | |

| Performance | Temp.fluctuation | ±0.3℃ |

| Temp.Uniformity | ±0.1℃ | |

| Material | Inner chamber material | SUS#304 Stainless steel plate+ powder coated |

| Exterior chamber material | SUS#304 stainless steel plate | |

| Insulation Material | Polyurethane foam 60mm | |

| Power supply | AC 1Ψ 220V;3Ψ 380V 60/50Hz | |

| Burning test equipment/burning test chamber/room | ||

| 1,Introduction:Products burning is targeted to remove initial failure,improving the reliability,it is the most economical product quality control.Otherwise it will cost a lots to improve the defects. | ||

| 2,Character:,Temperature control has self-adjusting function.‚,Overheating protection,overloading protection,Alarm indicator.ƒ,Anti-explosion chamber lamp. | ||

Optional accessories

1,USB port

2,Automatic humidity recorder

3,SCR(PID+SCR)control technology

4,Computer control software

5,Buffer chamber

6,Double doors

7,Wireless remote control network system

8,Testing trolley