Tel.: 8615989623158

E-mail: sales@grandetop.com

Tel.: 8615989623158

E-mail: sales@grandetop.com

It is applied to test the materials in heat-resistance, cold-resistance, dry-resistance, moisture-resistance. It is simple to operate and program easy to edit. It can show the set values and operative time.

It is applied to test the materials in heat-resistance, cold-resistance, dry-resistance, moisture-resistance. It is simple to operate and program easy to edit. It can show the set values and operative time.

Applied to test the prodcuts quality, such as electronic, plastic products, electrical appliances, instruments, food, vehicles, metals, chemicals, building materials, aerospace, medical care and so on.

The three-in-one design makes the equipment easy to operate and space-saving.Users can do different testings of high temperature,low temperature and costant temperature humidity condition in every single testing area.

Every system is entirely independant of each other,adopts 3 sets of refrigeration systems,3 sets of humidifying systems and 3 sets of controlling systems,so as to ensure stable and accurate controlling,and povide a longer service life.

Touch control & setting mode is totally controlled and locked up by automatic micro computer system with PID value automatic calculating ability.

Corresponding Standard of the Temperature and Humidity Test Chamber:

1.GB11158 high-temperature testing condition

2.GB10589-89 low-temperature testing condition

3.GB10592-89 high-low-temperature testing condition

4.GB/T10586-89 humidity testing condition

5.GB/T2423.1-2001 low-temperature testing condition

6.GB/T2423.2-2001 high-temperature testing condition

7.GB/T2423.3-93 humidity testing condition

8.GB/T2423.4-93 alternating temperature testing machine

9.GB/T2423.22-2001 temperature testing method

10.IEC60068-2-1.1990 low-temperature testing method

11.IEC60068-2-2.1974 high-temperature testing method

12.GJB150.3 high-temperature test

13.GJB150.4 low-temperture test

14.GJB150.9 humidity test

Technical parameters:

| Model No | GTH-072-(+10)-2P | GTH-162-(+10)-2P | |||||||

| Inner chamber size(mm)W*H*D | 400×400×450 | 600×450×600 | |||||||

| Exterior chamber size(mm)W*H*D | 1060×1760×780 | 1260×1910×830 | |||||||

| Performance | Temperature range | -80℃,-73℃,-60℃-40℃,-20℃,0℃,+150℃,+180℃,+200℃ | |||||||

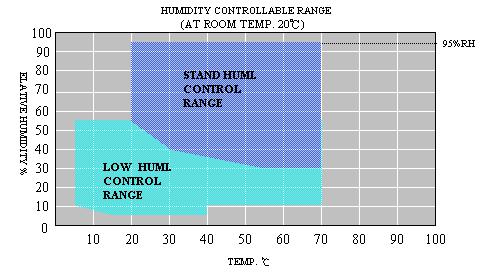

| Humidity range | 20%RH ~98%RH(10%RH ~98%RH or 5%RH ~98%RH) | ||||||||

| Temp.&Humi fluctuation | ±0.2°C, ±0.5%RH | ||||||||

| Temp.Humi.Uniformity | ±1.5°C; ±2.5%RH(RH≤75%),±4%RH(RH>75%)No-load operation,After stead state 30 min. | ||||||||

| Temp.humi resolution | 0.01°C; 0.1%RH | ||||||||

| 20°C~High TempHeating up time | °C | 100 150 | |||||||

| Min | 30 40 | 30 40 | 30 45 | 30 45 | 30 45 | 30 45 | |||

| 20°C~Low tempCooling down time | °C | 0 -20 -40 -60 -70 | |||||||

| Min | 25 40 50 70 80 | ||||||||

| Heating rate | ≥3°C/min | ||||||||

| Cooling rate | ≥1°C/min | ||||||||

| Material | Inner chamber material | SUS#304 stainless steel plate | |||||||

| Exterior chamber material | Stainless steel plate+ powder coated | ||||||||

| Insulation Material | PU & Fiberglass wool | ||||||||

| System | Air circulation system | Cooling fan | |||||||

| Fan | Sirocco fan | ||||||||

| Heating System | SUS#304 stainless steel high-speed heater | ||||||||

| Air flow | Forced Air Circulation(It enters at bottom and leaves at top) | ||||||||

| Humidification system | Surface evaporation system | ||||||||

| Refrigeration system | Imported compressor,Tecumseh compressor,finned type evaporator,air(Water)-cooling condenser | ||||||||

| Refrigerant | R23/ R404A USA Honeywell. R290A/R472A for EU | ||||||||

| Condensation | Air(Water)-cooling condenser | ||||||||

| Dehumidifying system | ADP critical dew point cooling/dehumidifying method | ||||||||

| Controlling system | Digital electronic indicators+S.S.R.With PID automatic calculation capability | ||||||||

| Operation interface | Grande Expertise in Temperature & Humidity Controller,Chinese-English Shift. | ||||||||

| Controller | Programmable capability | Save 120 profiles with up to 1200 steps each | |||||||

| Setting range | Temperature:-100℃+300℃ | ||||||||

| Reading accuracy | Temperature:0.01℃ | ||||||||

| Input | PT100 or T Sensor | ||||||||

| Control | PID control | ||||||||

| Communication interface | Equipped with standard communication interface devices USB,RS-232 and RS-485,enable the test chamber to be connected with personal computer(PC),to achieve multi-machine control and management at the same time.Standard: USB external memory port.Optional: RS-232, RS-485, GP-IB, Ethernet | ||||||||

| Print function | Japan Yokogawa Temperature Recorder(Optional accessories) | ||||||||

| Auxiliary | Limit Alarm,Self Diagnosis,Alarm Display(Failure Cause),Timing device(Automatic Switch) | ||||||||

| Accessories | Multi-layer vacuum glass observation window,Cable port(50mm),Controlling status indicator lamp,Chamber light,Specimen loading shelf(2pcs,position adjustable),Guaze 5pcs,Operation manual 1 set. | ||||||||

| Safety protection device | Over-heat protection circuit breaker,Compressor overload protection,Control system overload protection,Humidifying system overload protection,Overload indicator lamp. | ||||||||

| Power supply | AC 1Ψ 110V;AC 1Ψ 220V;3Ψ380V 60/50Hz | ||||||||

| Customized service | Welcome to Non-standard,Specail requirements,OEM/ODM orders. | ||||||||

| The technical information will be subjected to change without notice | |||||||||

Optional accessories

1,Low Humidity and Dehumidifying sytstem.

2,Inner glass door with manual operating ports.

3,Temp./Humi.Recorder.

4,Pure water treatment device

5,RS-485 interface can be linked to Personal computer(PC) and achieve multi-level control & recording software management.

6,Liquid nitrogen(LN2)/Liquid Carbon Dioxide(LCO2) fast cooling-down system.

7,Temperature change rate on average without load(Linear heating up and cooling down):5℃/min,10℃/min,15℃/min,20℃/min,25℃/min,RAMP Function.