Tel.: 8615989623158

E-mail: sales@grandetop.com

Tel.: 8615989623158

E-mail: sales@grandetop.com

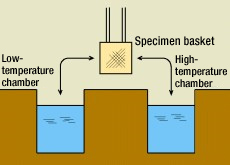

Liquid Thermal Shock Test Chamber,Cold and hot impact machine can be used to test material structure or composite material, in an instant by extremely high temperature and extremely low temperature continuous environment can endure degree, in order to in the shortest time test commits any heat bilges cold shrink caused by the chemical changes or physical damage.

Liquid Thermal Shock Test Chamber,Cold and hot impact machine can be used to test material structure or composite material, in an instant by extremely high temperature and extremely low temperature continuous environment can endure degree, in order to in the shortest time test commits any heat bilges cold shrink caused by the chemical changes or physical damage. Applicable objects including metal, plastic, rubber, electronics, pv, solar... And other materials, the products can be used as a basis of improving or reference.

Significant reductions in fluid usage make liquid thermal shock affordable

Purchasing a liquid thermal shock chamber needs close consideration of the long term operating costs. The specialized liquids used can easily evaporate, causing the loss of thousands of dollars of fluid per year, if not properly contained. Liquid-to-liquid thermal shock testing is typically conducted to apply very strong, repetitive thermal stress to test pieces. It can model a product's ability to withstand thermally-induced size changes, crack resistance, hermetic integrity, and changes in electrical properties. This form of testing provides a very rapid temperature shock recovery of conditions, and it can significantly reduce testing time by requiring shorter soaks and less cycles. The liquid thermal shock chambers have been built to meet the demanding test requirements, which has become a defacto industrial standard for semiconductor devices.

Applications:

1 Test physical changes of IC, PCB, ceramic semiconductors and other high polymer materials.

2 High and low temperature liquid tanks use forced mixing convection way.

3 Automatically move testing samples from up to down or left to right to preheating, precooling.

4 Use Garden D02TS in hot and cold chambers to reduce the cost.

5 Suitable for water cooling and air cooling.

Features

· Multiple mechanisms for reduction of fluid losses

· Automatic shutters at bath inlets

· Condensation pipe at the top rim of the high-temp bath

· Vapor recycling unit in the transfer area

· Designed for single (Galden) & dual-fluid (Fluorinert) use

· Easily located, requires only electric power hook-up

· Low noise of only 65 dBa

· Touch-screen controller

Technical parameters:

| Model No | GLTS-021-65-LW | GLTS-041-65-LW | |||

| Testing method | Two-liquid bath system with specimen basket transfer | ||||

| Test zone size W*H*D(mm) | 200*350*300*2Bath | 260*350*450*2Bath | |||

| Test zone size W*H*D(mm) | 1140*1785*1240mm | 1200*1785*1320mm | |||

| Performance | Hot bath | Preheat temperature range | +80℃~+200℃ | ||

| Temperature fluctuation | ±2℃ | ||||

| Temp.heat-up rate | Ambient temp.to+150℃ within 90min | ||||

| Temp.pull-down rate | +150℃ to +60℃ within 60min | ||||

| Cold bath | Precool temperature range | -60℃~0 | |||

| Temperature fluctuation | ±2℃ | ||||

| Temp.heat-up rate | -65℃ to 0 within 60min | ||||

| Temp.pull-down rate | Ambient temp.to -65℃ within 120min | ||||

| System | Circulation system | Sirocco fan | |||

| Heating system | SUS#304 stainless steel high-speed heater | ||||

| Cooling system | Imported compressor,Tecumseh compressor(or Bizer Compressor),finned type evaporator,air(Water)-cooling condenser | ||||

| Controller | TEMI990,8226,8227,8229 | ||||

| Thermal shock range | -65.00℃~00.00℃/+600.00℃~150.00℃ | ||||

| Testing time | 5min | 5min | |||

| Transfer time | Approximately 10 seconds | ||||

| Temp.resolution | 0.1℃ / 1 min | ||||

| Specimen Basket size(mm) | 100*180*200mm | 160*180*350mm | |||

| Specimen basket load capacity | 1C 2Kg | 1C 5kg | |||

| Controller | Color TFT LCD panel(6.5inch) | ||||

| Power supply | AC 1Ψ 220V;3Ψ 380V 60/50Hz | ||||